In the world of industrial manufacturing, efficiency and reliability are paramount. One of the key players in achieving such standards is Fristam Pumps, a brand synonymous with quality and performance in the fluid processing industry. Known for their robust design and engineering excellence, these pumps are pivotal in optimizing operations across various sectors. This article delves into how Fristam Pumps contribute to industrial efficiency, offering valuable insights for professionals seeking to enhance their systems.

Understanding Fristam Pumps

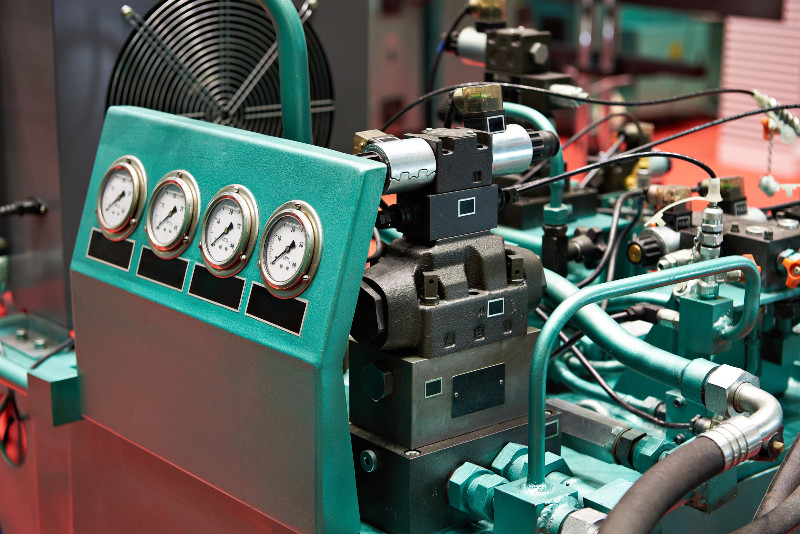

Fristam Pumps are renowned for their exceptional craftsmanship and durability. Manufactured with high-grade stainless steel, they are designed to handle a wide range of viscosities, temperatures, and pressures. The versatility of these pumps makes them ideal for numerous applications, including food and beverage processing, pharmaceuticals, and chemical manufacturing.

Key Features That Boost Efficiency

-

Superior Construction: The use of non-porous, corrosion-resistant stainless steel in Fristam Pumps ensures longevity and minimal maintenance. This material choice prevents product contamination and withstands the harsh conditions of industrial environments.

-

High Energy Efficiency: These pumps are engineered to maximize hydraulic efficiency, which reduces energy consumption significantly. Lower energy usage not only cuts costs but also supports sustainability goals within industries.

-

Adaptability: Fristam Pumps are designed to handle multiple tasks without the need for extensive modifications. This adaptability reduces downtime and increases productivity by allowing the same pump to be used for various processes.

-

Easy Maintenance: The straightforward design of these pumps enables easy assembly and disassembly, facilitating regular maintenance and quick repairs. This feature ensures that the pumps operate at peak efficiency with minimal operational interruptions.

Enhancing Process Reliability and Safety

The reliability of Fristam Pumps is unmatched, thanks to their robust design and precision engineering. This reliability ensures consistent performance, essential for maintaining product quality across production cycles. Moreover, the safety features integrated into these pumps help in preventing accidents and maintaining a safe working environment, crucial in any industrial setting.

Application in Industries

Fristam Pumps are instrumental across various sectors. In the food and beverage industry, they are used for transferring delicate ingredients without degradation. In pharmaceuticals, they maintain the integrity of chemical compounds through precise and contamination-free processes. Similarly, in cosmetics, these pumps handle sensitive materials like lotions and creams, ensuring consistent texture and quality.

Conclusion

Fristam Pumps are more than just equipment; they are integral components that drive industrial efficiency and reliability. Their robust construction, energy efficiency, adaptability, and easy maintenance make them invaluable in achieving operational excellence. By integrating these pumps into their processes, professionals can ensure enhanced productivity, reduced costs, and improved product quality—key metrics in any industrial operation. The durability and precision of Fristam Pumps not only fulfill immediate operational needs but also contribute to long-term success and sustainability in the ever-evolving industrial landscape.