Aluminum is used for a wide variety of products and in a broad variety of places. They are favored for a number of qualities that give them their niche uses. The aluminum as a material has an outstanding strength-to-weight ratio. They’re very light and yet very strong as favored in industries such as aerospace and aircraft manufacturing.

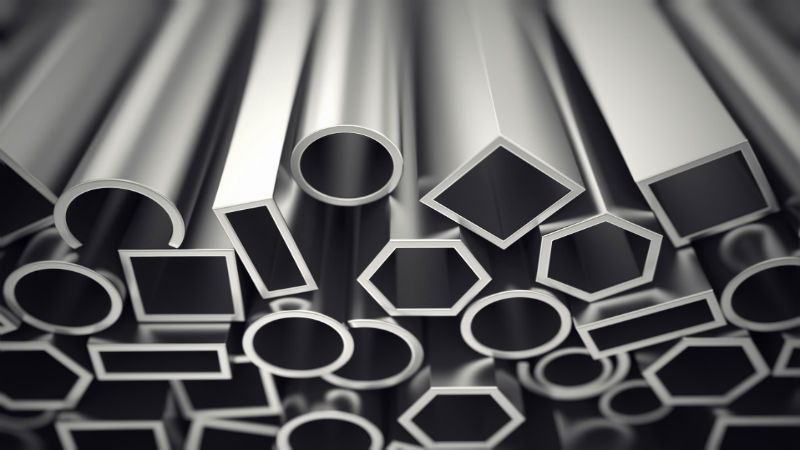

Aluminum metals are also naturally corrosion resistant. They don’t rust and break down as readily as other metals. And finally, they are very malleable, able to take on a very wide variety of shapes in different sizes. When it comes to 6061 aluminum plates as opposed to aluminum sheets, their difference is in their thickness. Aluminum sheets are thinner than 6 millimeters and anything more than that is considered cast or aluminum plates.

They are made from wrought aluminum which means they’re rolled, heated and shaped into plates. Or they are made through casting as you’d expect from Cast Tool or Jig Plate. One offers more durability while the other is more affordable.

These rolled metals are known as the standard 6061-T651that’s been popularized and made as a benchmark for years in branded names such as Alcoa’s Type 200 tooling plate and Kaiser’s Precision Plate. They have become the go-to material for machining used in transport for engines.

The thickness of aluminum material for both sheets and plates ranges from 0.025 inches to 12 inches allowing for a wide variety of uses.Whatever thickness you might need, consider having one with the expertise look into your requirements. Give us a call at 414-355-9611 for any questions on customized fabrication.